The following has been in effect since March 27, 1988 and is unmatched by anyone in the world…

First of all, The Money Back Guarantee: If you purchase a home from us and have the home erected by us, or one of our authorized crews, we’ll give you up to 10 days or until you continue construction on the home—whichever comes sooner—for you to approve of our home or our services. If you decide during that time period that you aren’t satisfied (with the quality of our home and our services) notify me and we’ll (within 30 days) dismantle the structure we originally erected, remove it, and refund all the money you gave us.

Secondly, the structural guarantee: Our unique homes are not so easy to design as they might seem. Our structures require special expertise in design, timber grading, manufacture, and erection to insure satisfactory long term structural performance. Through years of experience and years of working with major code agencies, we have developed structural design systems that enable us to guarantee your home structurally for as long as you own it. We guarantee that every timber in your home is individually graded for it’s specific structural load in the home and that structural specifications are in compliance with major code agency guidelines.

The pre-cut packaged home industry is popular with do-it-yourselfers and owner contractors. The challenges are great, but so are the rewards. The banks usually require the homeowner be experienced, or at least show they have the ability to complete the job. Since your equity position will not require “permission” from the bank, the only questions you need to ask yourself are:

- Do I have the time?

- Do I have the ability and patience?

- Is it something I enjoy doing?

- If the decision to “build yourself” is driven by finances, will the time away from employment offset the savings gained by doing the work yourself?

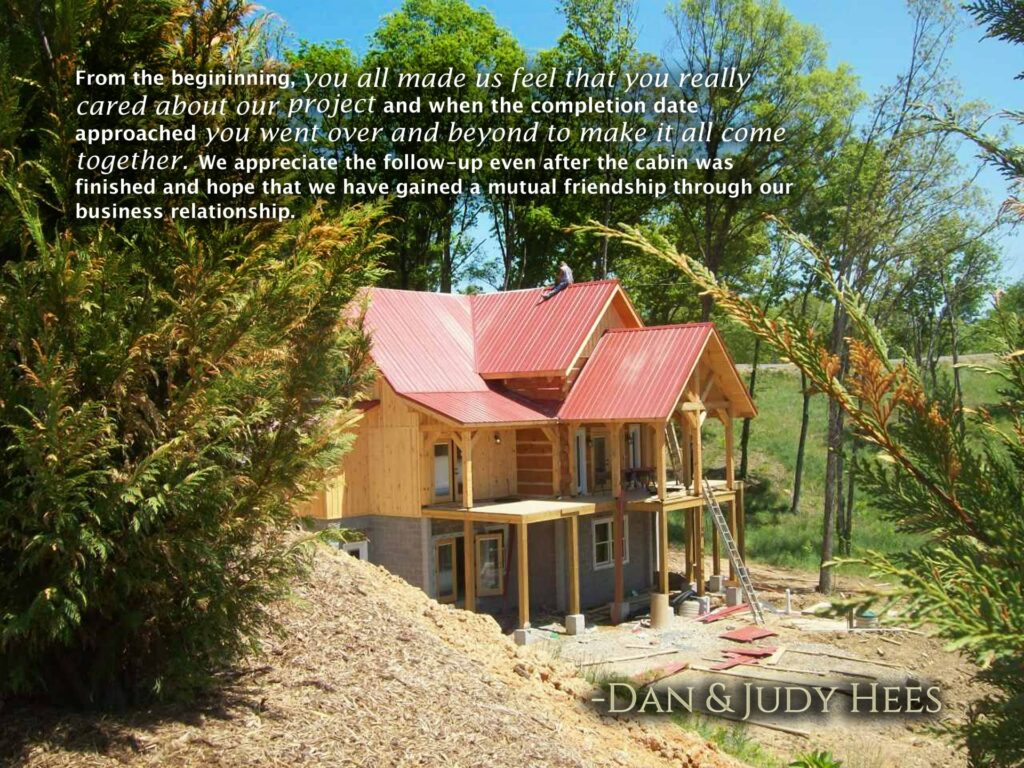

Hearthstone makes the process of “building yourself” easier by providing the erection and dry-in services with our packages. This results in a temporarily “dried-in” shell for you to complete at your own pace. You’ll need to prepare the foundation and subfloor ahead of delivery (we provide the plans), but then we get most of the heavy lifting done and structural work completed (our crews have cranes and the pricing is included with erected shell).

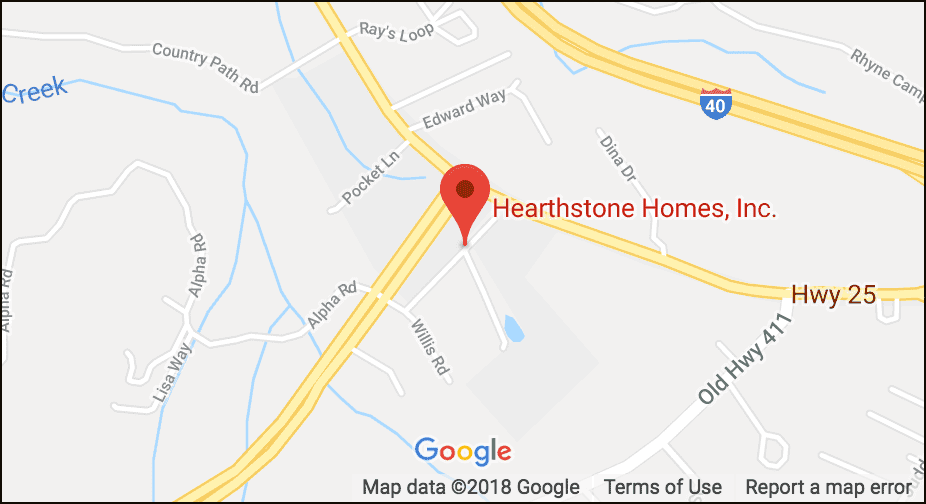

If you would like a detailed Proposal, see an existing Hearthstone or speak with an owner who accomplished what you are considering, let me know.

Hearthstone’s full packages include structural, specialty, common, erection and possibly dry-in services (depending on time of year and availability). To this you need to add the cost of freight, crew travel and state sales/use tax. The erection and dry-in pricing assumes site access allows for our tractor trailer trucks to deliver near the foundation and the crane will be positioned on the uphill side. Shuttling of materials and tight job sites require more money.

Some areas of the country are more expensive than others and your finish tastes will also vary the total costs. The General Contracting services (hire a GC or do-it-yourself) and the amount of owner involvement in the finish work also effect the costs.

One way of ballparking is the average cost per square foot–although I’d like to see the cost per cubic foot used instead since the interior volume of the home dictates more of the cost than heated floor area square footage. For average sized 2000 square foot homes, the total construction costs are currently running $175 to $250 per square foot of heated area, including our package. Smaller homes tend to be higher per square foot and larger homes tend to be smaller per square foot.

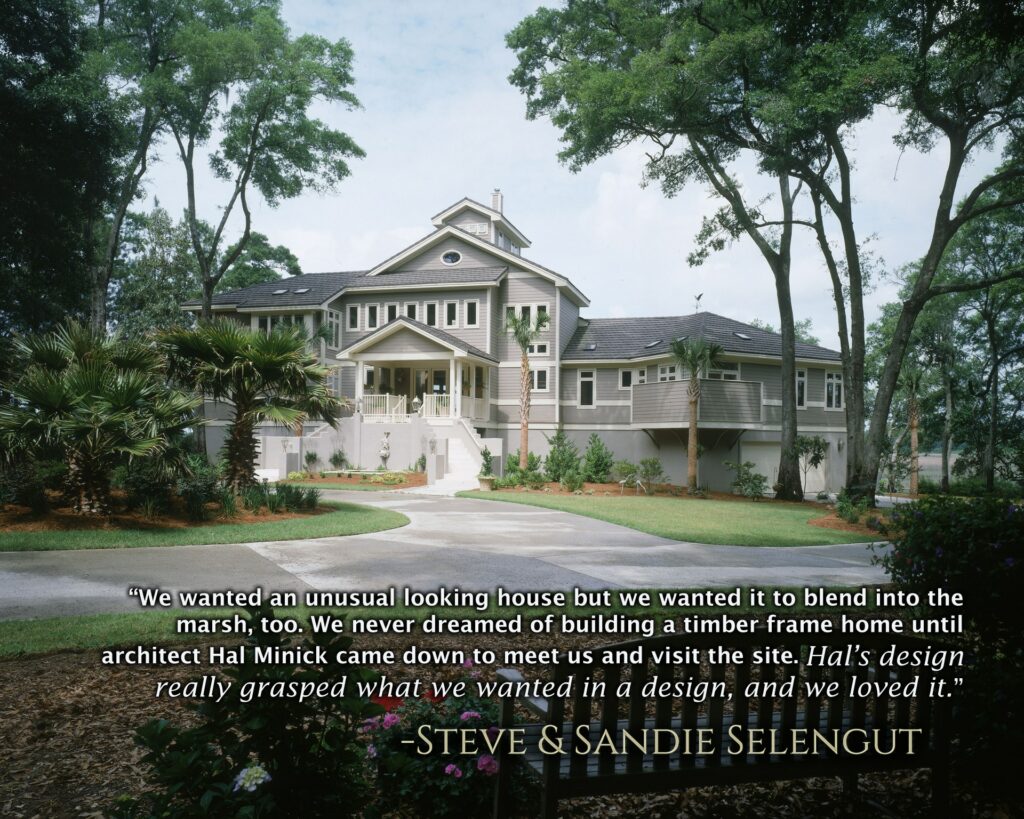

We have found over the years that most people get what they pay for and very few get more! If a builder is coming in too high (compared to the other bids) it doesn’t always mean that he is earning more money. We recommend you see examples of the work and nail down the specifications before you decide.

Expectations are everything. If the builder’s expectations are greater, it may influence the finish quality and/or service and he’ll be priced too high. If they are lower, he won’t provide what you expected. Matching expectations is the key to any successful endeavor. Let us know if we can be of help locating an experienced builder.

A log on log system contains slightly more “mass” than a log home with Chinking. An average R-Value for a six inch thick log is R-8.04, regardless of log on log or Chink style. The 6×12 Hearthstone Chink space is loaded with insulation and this helps boost the average R-Value of the entire wall to R-12.1, and still retains the “mass effect”.

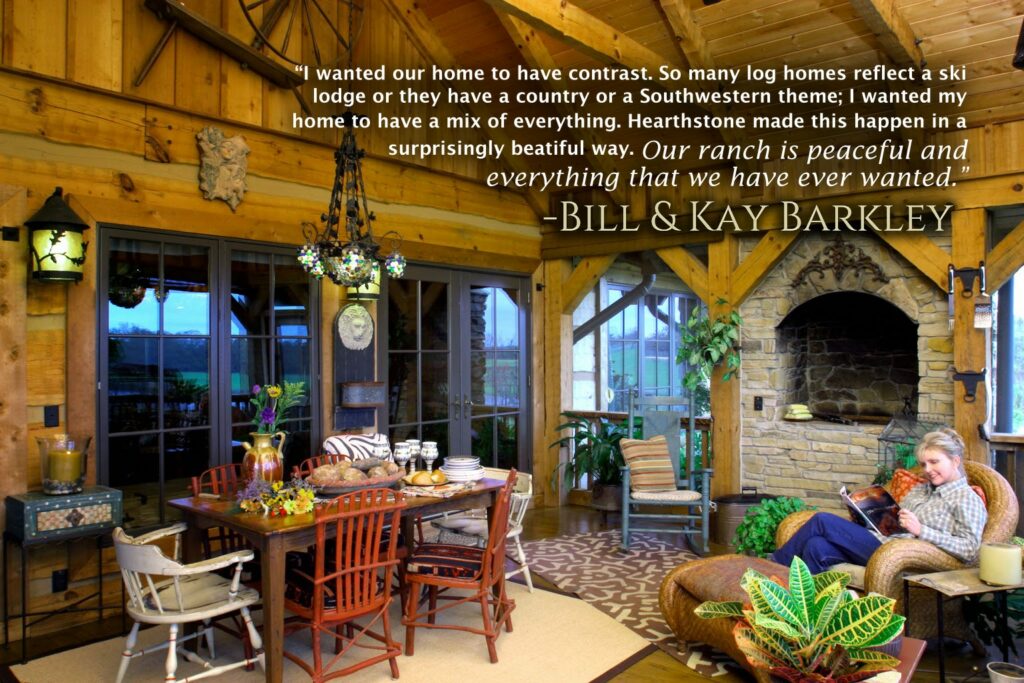

Even though we can prove how tight and energy efficient our log system is compared to others, I recommend you base your decision on aesthetics. If you like the look of a log on log (with a small amount of Chinking), there are several companies that do good work. Log on log electrical wiring is challenging, limited and will cost more. Log lengths are shorter (longest usually 16′) and butt joints are common. Erection fees are usually higher because of all the lagging, short logs and electrical wiring delays. If you decide to base your “buying” decision on package costs, let us show you why our package is worth it.

The R-Value of the wall log will vary with the species of wood. We use primarily Eastern White Pine for our wall logs, in 6 or 8 inch thickness. For a 6″ wall, the wood material is R-7.2. If you combine the outside air film of 0.17″ and inside air film of 0.68″, a 6″ thick log is approximately R-8.0. Averaging this with the increased R-Value of the Chink space (See Above), our total wall average is approximately R-12.1 for our 6×12 system with a 4 inch Chink space.

Keep in mind R-values are only one factor in determining energy efficiency and comfort. The other two factors are air infiltration and “mass effect”.

The finished cost will have more to do with the “cubic footage” than the square footage. Cubic footage is related to the roof system. Open cathedral ceilings with exposed hewn rafters and tongue and groove ceilings are very attractive and are what most folks visualize when they think of log homes. 1300 square feet with this type of roof system may cost $260k+ on a crawl space or unfinished basement in East Tennessee.

A flat truss roof system with 8′-0″ drywall ceilings is less expensive to build, possibly $220k on a crawl space in East TN.

I’d expect these prices would afford hardwood floors, stone fireplaces, covered porches and some site work. Our package cost for a dried in shell would usually cost around 40% of these total costs with the balance set aside for local labor and materials. Let us know if we can provide a detailed Proposal.

Drying in a vacuum makes all the difference. In a vacuum, moisture exits the log at a lower temperature and at a faster rate than in a conventional kiln. This allows us to get the moisture content in our huge logs and timbers down to a meaningful moisture content – consistent throughout the timbers – at a reasonable cost and amount of time. The entire process is completely tailored to both performance and efficiency.

The moisture content throughout the logs and timbers can be reduced to a meaningful level. Previously, the term “kiln dried” logs didn’t mean much, because it was far too costly – in time and money – to dry large timbers to an internal moisture content low enough to improve the value and utility of the timbers.

The vacuum chamber is large – and is designed to dry large timbers. Previously, kilns were designed for drying boards – not logs and timbers. They were suitable only for short, small diameter logs and timbers, and even then the results were not acceptable. Timbers up to 40’-0” in length will fit in our kiln.

The drying process within the chamber itself is highly complex, automated, and computerized. This solves the problem of uneven drying when trying to dry logs and timbers in older, conventional kilns. The new process lowers drying times and reduces defects.

The time in the kiln is dramatically shortened. Previously, kiln time was 3 or more times as long. This was especially true for large timbers – and even then, less than acceptable results had to be tolerated.

To learn more about vacuum-dried timbers, please visit Http://Heartdried.Com

Hearthstone uses ShellGuard™ on all sill logs as standard practice. We’ll occasionally use YardGuard™ (for a fee that is covered in Purchase Agreement) with packages that have already been cut and client delays delivery so blue stain doesn’t set in too bad.

Yardguard™ is designed to be applied to freshly-sawn wood, timber, and logs within 24 hours after they are sawn or peeled. Yardguard™ is a temporary mildewicide and UV inhibitor to provide temporary protection while the logs are being stacked, or lying in the manufacturer’s yard.Yardguard™ does not stop any wood ingesting insects and does not provide long term protection from mold, mildew and graying from UV light.

Shellguard™, on the other hand is designed as a termiticide and preservative that not only stops damage from wood-ingesting insects, but also stops the formation of wood decaying fungus. Shellguard™ is a borate-based product that is applied before the wood has any finish applied. Then, when the Shellguard™ dries completely, you can apply the Lifeline™. The Shellguard™ has to have a finish applied and maintained, if not, it will leave the wood after a period of time.

In regard to your question about applying Lifeline™ stain over Shellguard™. The customer need only to wait until it is dry to the touch early in the mornings. Dry time will vary greatly with temperature and humidity. Cold weather applications of Shellguard may take six weeks, but in the summer months—usually 72 hours.

Having began our career in log home restoration many moons ago, we’ve worked with all types of timber. This includes 200 year old ‘seasoned’ material, trees salvaged from the river bottoms and lakes, timbers air dried naturally for two years, freshly cut trees from the Eastern and Western US and Canada, standing dead, laminated logs and now vacuum-kiln material. We’ve seen them all. All this wood has one thing in common; It still shrinks and it still settles.

To what degree is subject to debate. Some of this shrinkage is measurable. There are complex calculations to determine the amount shrinkage in fractions of an inch based on moisture content and species. But these aren’t adjusted for real-world application such as the percentage of “heartwood” vs. sapwood”, the altitude or latitude in which it was grown (shortness of seasons), the tightness of rings (old growth vs. new) and the type of cut (boxed heart vs. free of heart center—FOHC). If you can dry the timber down to 12% consistently, you will see minimal shrinkage thereafter. But shrinkage from moisture only accounts for HALF of the settling.

The other half comes from compression. This is driven by the weight of the roof (with a full snow load). It is helped by the weight of the second (and third) floors. And it is accelerated by the use of throughbolts and compression springs. The longer you take to build a home and the later you design and install the finished stair system, the better.

Some of this shrinkage and settling is unpredictable. Relative humidity, snow loads, prevailing winds, exposure to rain and sun, type of fasteners, throughbolts, adjoining structures, covered up screw jacks, hidden fasteners, window & door trim and interior partitions nailed up tight. All real-world issues that should be managed.

We have seen 200 year old bone-dry material in a dovetailed system compress and settle over one inch in nine feet after the weight of the floor and roof is applied. For this reason, we still engineer for shrinkage and settling in our log homes, even if HeartDried down to 12% moisture at the core. In fact, the new International Residential Code calls for log home manufactures to detail for shrinkage if they experience more than 1/2″ settling in every 8′-0″ of height. It is one thing to detail it, and another to see that it gets done.

Chink me now, or Chink me later! In the old days, there was mortar mix and chicken wire to use between the hewn logs. We would painstakingly splice and dovetail these old timbers and make certain it was perfect. During the higher humidity summer months, these joints would swell tight. Come winter when humidity dropped, these same joints opened up ever so slightly.

Then came PermaChink™. Making the home weather tight around the Chink joints became easy. It stretched and compressed and moved with the seasons. Attractive colors were added the battle of the Chink space was solved.

But what about log-on-log? Over the years, we’ve seen many folks initially object to “that white stripe” and rule out our Chink style for someone else’s log on log. Then after two good years of living in the home and dealing with real-world issues, they’re back to caulking or Chinking the seams to make it perfectly weather tight.

A solution for these log-on-log clients has finally arrived in custom Energy Seal™ colors to match the Lifeline stain. No more worry about last minute touch up or sealing gaps in trim with caulking that doesn’t match. For those who don’t want the color and performance of Chinking, they now have an attractive alternative with Energy Seal™. A case of interior and exterior should be sent with every home sold. Maybe the old saying should change to “Chink me now, or Seal me later”?

We are happy to answer any other questions that you may have. Please email us at [email protected] with your questions!